Sublimated archery jerseys are made using a special printing process that involves transferring dye onto a polyester fabric. Here are the steps involved in the sublimation process:

1. Design

The first step in making a sublimated archery jersey is creating a design. This can be done using graphic software, Adobe Illustrator or Photoshop. The archery jersey design can include the team's name, logo, shooter names, and any other graphics or text.

2. Printing

After completing the design, we will use the dye-sublimation printerto printit onto a special transfer paper. The special sublimation inks used in the printer will turn into gasses when in a heated condition.

3. Transfer

Once the printing is complete, the polyester fabric of the archery shooter jersey is then placed under the printed transfer paper. The heat press machine presses on both of them to transfer the sublimation ink from the paper onto the fabric, at a high temperature and pressure.

4. Cooling

After the transfer is complete, the fabric is cooled to set the dye. This ensures that the dye becomes a permanent part of the fabric and will not fade or peel off over time.

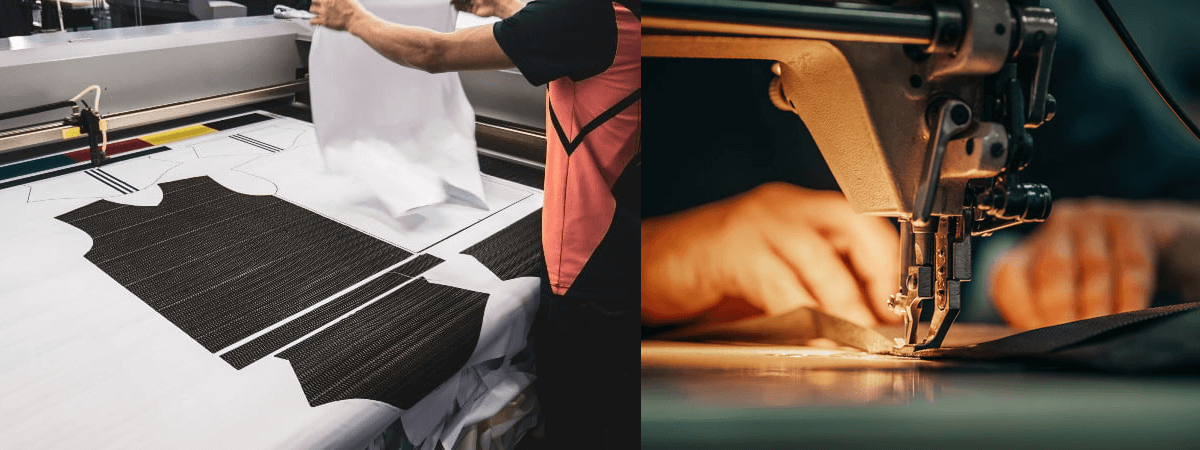

5. Cutting and Sewing

Once the fabric has cooled, it is cut into theproper shapes and sizes for the archery jerseys. The pieces of cloth patterns are then stitched together to create the finished jerseys.

Sublimated archery jerseys offer several benefits, including vibrant colors, high-quality graphics, and durability. The dye is absorbed directly into the fabric, resulting in a smooth finish that won't crack, peel, or fade. Additionally, the polyester fabric is lightweight, breathable, and moisture-wicking, making it an ideal material for archery apparel.